Test What You Know about Pneumatics

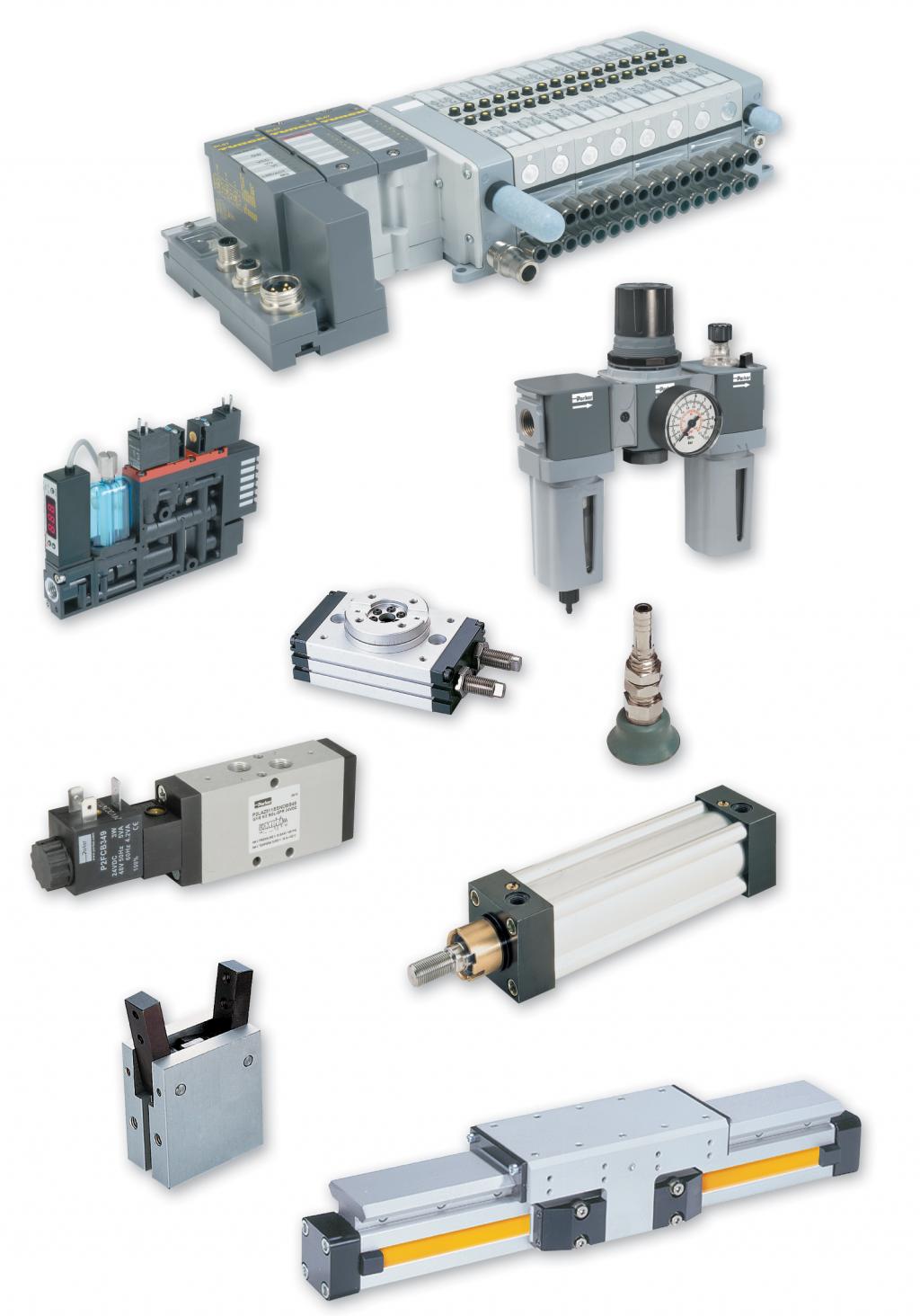

Pneumatics technology is the gentle giant of power transmission in factory automation. Compressed air is often applied for its cushioning capabilities, providing a more subtle touch than hydraulics or electromechanical drives can in many material handling applications. However, the versatility of pneumatic cylinders requires application expertise to convert them from an expense to a returned investment. Here are five tips to help you magnify that ROI:

Pneumatics technology is the gentle giant of power transmission in factory automation. Compressed air is often applied for its cushioning capabilities, providing a more subtle touch than hydraulics or electromechanical drives can in many material handling applications. However, the versatility of pneumatic cylinders requires application expertise to convert them from an expense to a returned investment. Here are five tips to help you magnify that ROI:

Avoid side-load mounting

Cylinders are designed for push-pull stroke action, and side-load mounting can result in misalignment, off-center loads, rod deflections, imprecise tie-rod torque or long stroke action. When installing, the cylinder piston rod should be aligned with its mating machine component and inspected in both the extended and retracted positions. Improper alignment shortens cylinder life due to excessive rod gland and/or cylinder bore wear.

Prevent contamination

Solids such as particulates, pipe rust and scale and thread sealant debris can curtail seal life, plug orifices and damage surface finishes. Keep manufacturers’ port plugs intact and in place until the system is fitted with piping. If that doesn’t happen, clean the piping thoroughly before connecting it to cylinder ports. In all compressed air applications, moisture collects in components, blocking orifice flow through, diluting pre-lubrication grease, adulterating airline lubricants, damaging barrel or rod finish and freezing in cold weather. Consider using stainless-exercised steel rods and fasteners or special coatings or epoxy paints. And watch out for oils resulting from air compressor lubrication carryover or synthetic oils that are typically incompatible with air-line components. Such oils can swell seals and plug orifices. Use seals compatible with oils.

Consider dry and lubricated service options

Cylinders used in high or fast cycle rates typically generate significant shock loads at end of stroke, and heat generated by the system can exceed component temperature limits. Consider selecting a “non-lube” cylinder, adding a lubricator to the air-prep system or integrating an injection lube system. An air-cushion cylinder is another option, as are adding a shock absorber or lowering system pressure via a regulator on the return (non-working) side of the cycle. Finally, adding flow control to the cylinder can help, as long as high speed is not required.

Observe component limits

Running cylinders over their capacity applies higher stress and friction to seals. The result is broken rod ends and disintegrated actuators. And if the system contains speed control or energy-absorbing devices, pressure spikes can double or triple normal system pressures. Make sure rod accessories are firmly shouldered against it by threading all the way down or by using spacers or shims. Alternatively, consider increasing rod-thread size or using a studded rod end.

Customize your own checklist

Am I using fittings that contaminate?

When using plastic tubing, are my cuts straight and smooth for proper sealing?

Am I using new tubing (hose) and connectors to eliminate contamination?

Do my filters need changing?

Are fasteners properly torqued so tie-rods are secured?

Is the product warranty in effect and are cylinder faults covered?

Are my performance equations accurate?

Properly applied, operated and maintained, pneumatic cylinders will help keep equipment running as the OEM intended. Visit Parker Pneumatic Division for more information.

https://youtu.be/cQd8EGJ3SKo