- Fundamental: PC-Base Control

- ICONIX TECHNOLOGY SDN BHD

0 inquiriesNegotiable

- Optional Advance Modules

- ICONIX TECHNOLOGY SDN BHD

0 inquiriesNegotiable

| Price | Negotiable |

| Delivery | MalaysiaPulau PinangWithin 3 days after payment |

| Insufficient stock for this product |

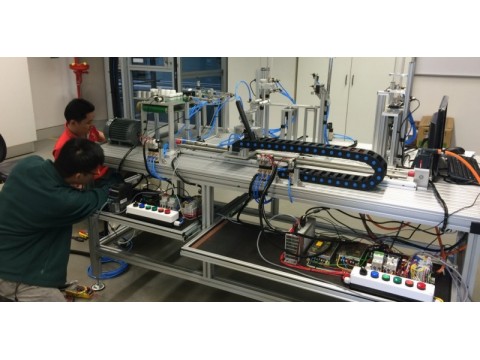

Workstation Function

Our Flexible Manufacturing System (FMS) training kit system is an automatic production line trainer. It is installed on an aluminum alloy rail, compose of delivery unit, loading unit, assembly unit, processing unit and sorting unit. Our Flexible Manufacturing System Training kit is developed with practical, expandable, modular and flexibility in mind.

Workstation Purpose

The FMS systems is designed to allow students to experiments and tinker with a simulated production based system. Each of the unit have their own independent control panel that allows students to separate the unit from one another.

The workstation covers topics such as relays, pneumatic cylinders, and different types of sensors, servo motor, ac motor, PC-Based PLC controllers and many other more.

Major Components

| Component | Unit |

| Loading Unit | 1 |

| Delivery unit | 1 |

| Processing Unit | 1 |

| Assembly Unit | 1 |

| Sorting Unit | 1 |

| Servo Motor with Encoder Feedback | 1 |

| Servo Motor Driver | 1 |

| AC Motor | 1 |

| AC Motor Driver | 1 |

| Touch Screen Panel | 1 |

| Industrial PC | 1 |

| Automation Software – PLC Control | 1 |

| Control Panel with Digital IOs | 5 |

| Aluminium Table Top | 1 |

| Training Manual | 1 |

Dimension :

3m x 3m x 2m (Width x Length x Height)

Pre-requisite knowledge:

PLC Programming, TwinCAT, Sensors, Pneumatic Cylinders, Motor Drivers

Our Commitment:

Iconix Technology provides on-site support, training and manual for all of our product. We uses Beckhoff PC-Based Technology that ensure ease of future expansion. Our knowledge and experience with both the academic and industry allow us to provide relevant and practical training solutions that are cost-effective and top-notch quality

Estimate Lead Times :

90 Days

Contact:

Email: info@iconixtechnology.com

Number: Ren – 0162782787

0 inquiriesNegotiable

0 inquiriesNegotiable